"This summer I've been going out into the garden early every morning in my pyjamas. Silk pyjamas, of course. I wasn't being lured out by the balmy air of a new summer's day because, actually, it has been a cold, wet season here in New Zealand. No, I would wake up and my first thought was for the needs of the newest additions to our household: fourteen pet silkworms. A peek into their box in the sunroom would see them raising up their heads in expectation of food. So out I would go to pick fresh mulberry leaves for the hungry caterpillars. And every four hours thereafter. For four weeks! Luckily we were having a staycation this Christmas.

It certainly puts into perspective the effort required to produce the several hundred cocoons needed to make one Silkbody garment.

After four weeks the first of our pet silkworms started to build their incredible silk cocoons. We waited patiently for the moths to emerge but feared that since we moved them from the warm sunroom at home to the Silkbody shop, the cold nights were preventing them from metamorphosing. They are sensitive creatures! Nevertheless, three weeks later the first silk moths began to appear. What an exciting day that was. There were shrieks of delight from us all as the first two emerged; the first being a female and the second evidently being a male keen as mustard, because they were mating within five seconds! I will keep the eggs they lay in the fridge until spring, when there will be fresh leaves on the mulberry bushes for the silk caterpillars to eat. I do hope they hatch!

It's been such a fascinating project, following the silkworm's lifecycle and witnessing the production of silk - in my home, no less. During 15 years in business selling silk products I had never come across any silkworms in NZ. It was thanks to the wonders of social media that we took delivery of these caterpillars from Auckland before Christmas. What a treat and one that I hope to repeat if the caterpillars hatch out in the spring."

Silkbody designer Emily Cooper

Each Silkbody garment carries the story of its evolution - from the finest fibre spun by the tiny silk caterpillar, to the incredibly lightweight, luxurious finished garment.

Take a look at the snapshot below of the process for the commercial production of Silkbody's silk in China. It's worth noting that the production of silk (sericulture) still follows the same methods that were developed 5000 years ago in China. That's 3000 years BC! That's a very long time ago, making silk a truly amazing, ancient fibre. We're so lucky to be able to wear a fibre today that was reserved only for royalty for many centuries - and understandably so when you learn how it is produced!

1. Every Silkbody garment begins with a tiny caterpillar hatched from an egg laid by the silk moth.

2. Clipped morus alba (white mulberry) growing in the fields.

3. Mulberry leaves are picked fresh daily to be fed to the silk caterpillars.

4. Silk caterpillars are voracious eaters.

5. After about 20 days of eating they start to build their cocoons of silk.

6. The farmers sell the completed cocoons to the factory for processing. In commercial production the moths are not allowed to emerge because they would break the continuous silk fibre and the cocoon couldn't then be unwound. So they are stifled before they emerge.

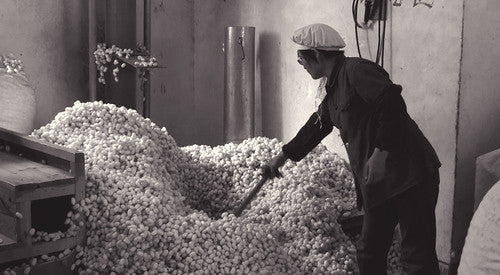

7. At the reeling factory the cocoons are sorted.

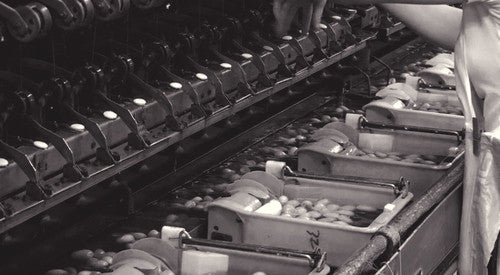

8. The cocoons are unwound to remove the silk.

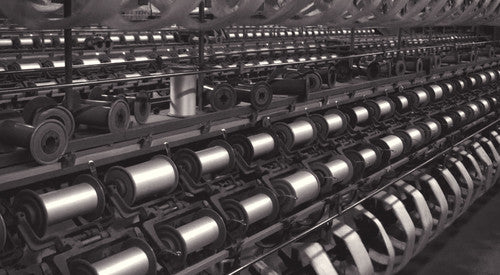

9. Reeled silk is transferred to spools ready for making into Silkbody fabrics.

6 comments

Hi Emily,

Fabulous garments and how imteresting to know that you have some silkworms in NZ.

Are you going to grow more Mulberry trees and are they white or black?

Lea

Leave a comment